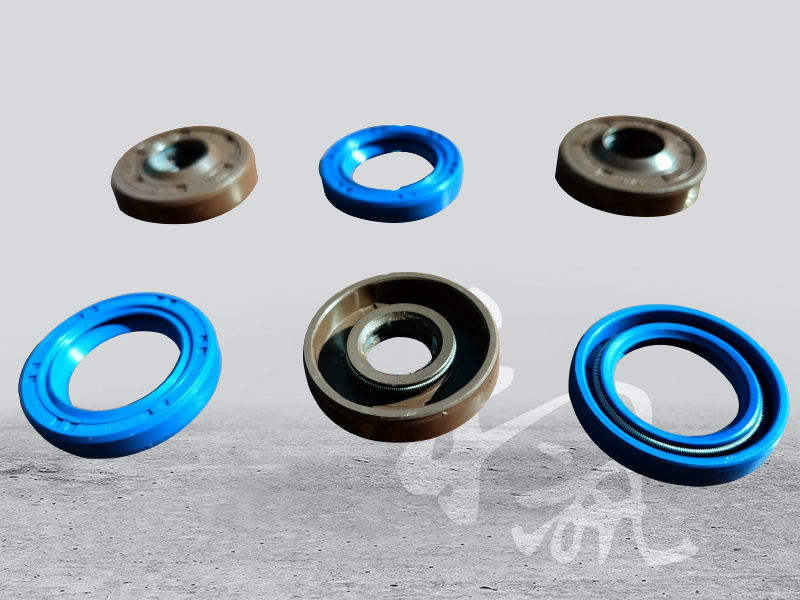

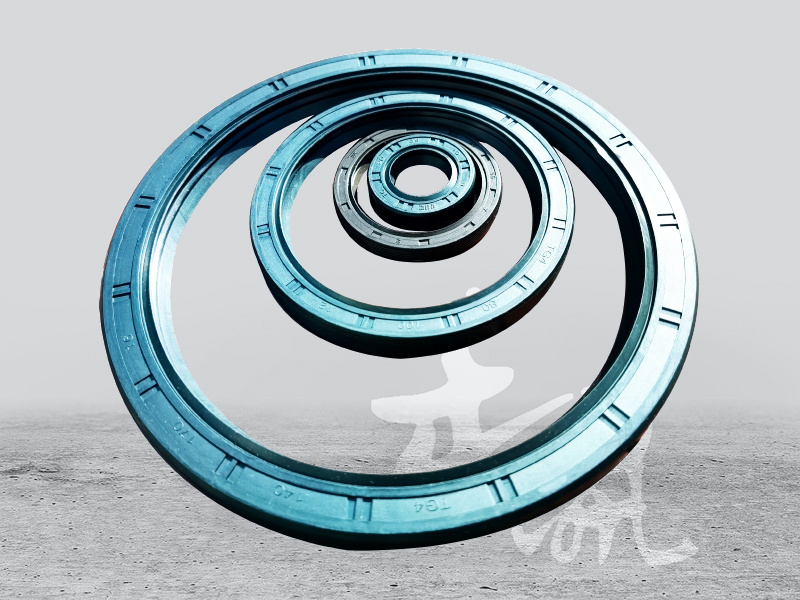

The sealing principle of the skeleton oil seal: Because there is an oil film controlled by the oil seal edge between the oil seal and the shaft, this oil film has fluid lubrication characteristics.

The transmission parts need to be lubricated parts and output parts isolation, so as not to let the lubricating oil leakage, usually used for rotating shaft, is a kind of rotating shaft lip seal. The skeleton is like the steel bar in the concrete member, which plays a strengthening role and keeps the oil seal in shape and tension.

The rubber ring and metal ring are integrally bonded and vulcanized. It is a sealing ring used to seal thread and flange connections. The ring includes a metal ring and a rubber gasket.

The choice of oil seal should be based on the sealing medium and working conditions. The sealing medium needs to choose the material of the oil seal. The working conditions mainly consider the use pressure, working line speed, and working temperature range.

Fluorine rubber seals, when used for engine sealing, can work for a long time at 200 ℃ ~ 250 ℃, and work for a short time at 300 ℃. Its working life can be the same as the engine repair life, up to 1000~5000 flight hours (time 5~10 years)

Fluorine rubber skeleton oil seal

Before installation, the oil seal should be smeared with lithium base ester added with molybdenum disulfide between the lips to prevent dry grinding of the lips and affect the interference of the lips when the shaft starts instantly, and should be assembled as soon as possible. Install the oil seal seat of the oil seal. If it is not installed immediately, it is recommended to cover it with cloth to prevent foreign matter from adhering to the oil seal. Be sure to clean hands or tools with lithium-based grease.

Address: Economic Development Zone, Julu County, Xingtai City, Hebei Province

Landline:0319-3795888

Fax:0319-3798886

Focus on us