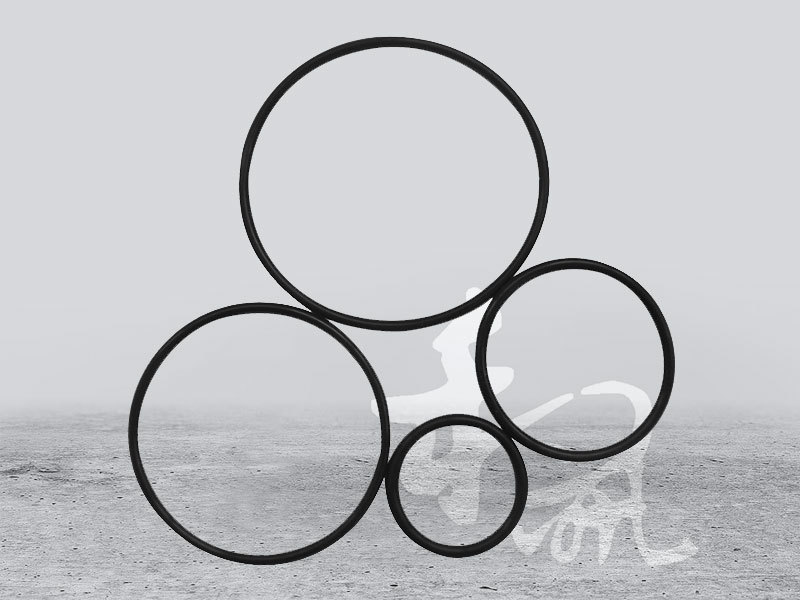

O-ring is a rubber sealing ring with a circular cross-section. Because its cross-section is O-shaped, it is called O-shaped rubber sealing ring, also called O-ring. It began to appear in the middle of the 19th century, when it was used as a sealing element for steam engine cylinders.

O-ring specifications mainly include UHSO ring specifications, UHPO ring specifications, UNO ring specifications, DHO ring specifications, piston rod O-ring specifications, high temperature O-ring, high pressure O-ring, corrosion-resistant O-ring, wear-resistant O-ring.

O-ring is suitable for installed in a variety of mechanical equipment, in the specified temperature, pressure, and different liquid and gas medium, in the static or motion state from the sealing effect.

The choice of O-ring hardness is more important. Such as a power station pump turbine hardness of 70(Shore) sealing ring, often peeling, or even transverse cut, after the use of 85~90(Shore) sealing ring, the effect is ideal.

The main chain of silicone rubber is composed of silicon (-si-o-si). It has excellent heat resistance, cold resistance, ozone resistance and atmospheric aging resistance. Good electrical insulation properties. The tensile strength is worse than the general rubber and has no oil resistance.

With the development of industry, fluorine rubber O-rings are widely used in automobiles, electronics, aerospace, ships, etc., which require relatively high precision, high temperature resistance, high wear resistance, and harsh working environments. With the development of industry, fluorine rubber The material is also constantly improved and innovated.

Address: Economic Development Zone, Julu County, Xingtai City, Hebei Province

Landline:0319-3795888

Fax:0319-3798886

Focus on us