Fluorine rubber seals, when used for engine sealing, can work for a long time at 200 ℃ ~ 250 ℃, and work for a short time at 300 ℃. Its working life can be the same as the engine repair life, up to 1000~5000 flight hours (time 5~10 years)

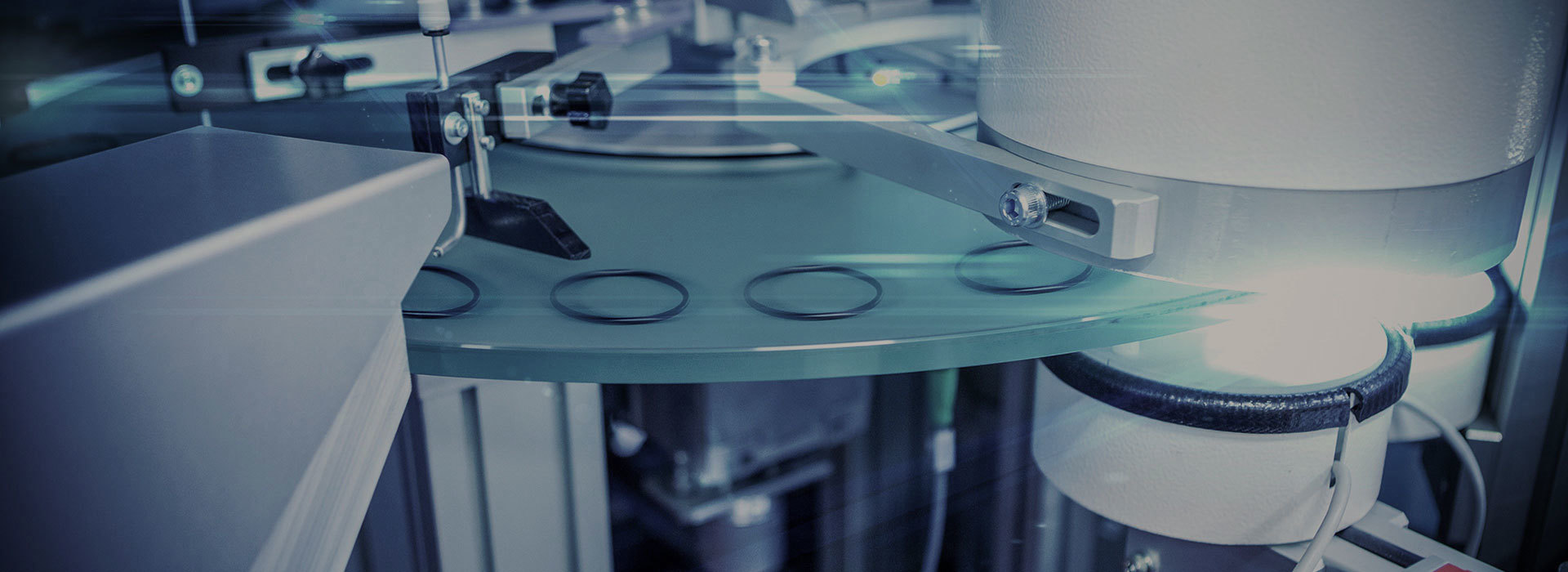

Fluorine rubber skeleton oil seal

Before installation, the oil seal should be smeared with lithium base ester added with molybdenum disulfide between the lips to prevent dry grinding of the lips and affect the interference of the lips when the shaft starts instantly, and should be assembled as soon as possible. Install the oil seal seat of the oil seal. If it is not installed immediately, it is recommended to cover it with cloth to prevent foreign matter from adhering to the oil seal. Be sure to clean hands or tools with lithium-based grease.

The main chain of silicone rubber is composed of silicon (-si-o-si). It has excellent heat resistance, cold resistance, ozone resistance and atmospheric aging resistance. Good electrical insulation properties. The tensile strength is worse than the general rubber and has no oil resistance.

With the development of industry, fluorine rubber O-rings are widely used in automobiles, electronics, aerospace, ships, etc., which require relatively high precision, high temperature resistance, high wear resistance, and harsh working environments. With the development of industry, fluorine rubber The material is also constantly improved and innovated.

Address: Economic Development Zone, Julu County, Xingtai City, Hebei Province

Landline:0319-3795888

Fax:0319-3798886

Focus on us